Mechanical Integrity Test / Crush Test

About Testing

The market for lithium-ion batteries is growing rapidly – and therefore also the need for specialized tests. Having been involved in this field of technology from the very beginning, our customers benefit not just from our experience, but also from our flexibility and ability to adopt tests to specific needs.

No matter if you are a start-up company, development service provider or OEM – we will be happy to advise you on what you need for your battery testing system.

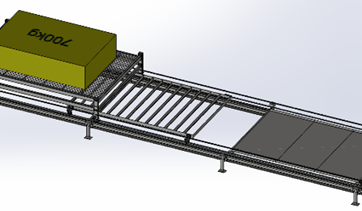

Mechanical Integrity Test / Crush Test

Various profiles of the crush plate can be implemented.

Various battery sizes are possible.

Tester type: Hydraulic

Supported Standards for Mechanical Integrity Test / Crush Test:

SAE J2464, SAE J2929, IEC 62660, UN/ECE R100, Freedom CAR

- Maximum Stroke: 700 mm

- Maximum Load: 300 kN

- Speed: 0 mm/s to 19 mm/s

- Table Size: 160 cm x 220 cm

- SOC: 0 – 100 %

- Temperature: 20°C – 60°C

It is important to understand exactly the needs of our customers.

We want to make the process easier for you. Please help us to improve our service for you!

Feedback and criticism is welcome at GTL to improve the service.

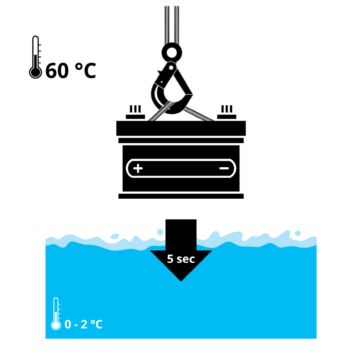

Abusive Tests

The GreenTestingLab is specialized in development accompanying battery tests on cell, module and system level with a focus on abuse testing as well as tests according SAE J2464, SAE J2929, ISO 12405, IEC 62660-2 (3), UN/ECE-R100.02, UL 2580, USABC, Freedom CAR, KMVSS 18-3, AIS-048, QC/Txx among others.

Feel free to ask for specific abusive and electrical tests.

customized abusive tests.

Get in touch with us

Get in touch with us